During my candy-dyeing experiment, I made roving that I was pleased with, but once I’d spun it and plied it with itself, I didn’t like the resulting yarn. I couldn’t find anything on the interwebs about how color changes through plying the same colorway. There are numerous examples of plying with neutrals, and there’s this nice Knitty article about how color changes when drafting vs. plying. So this experiment is to try and sort out how color changes through plying within the same colorway.

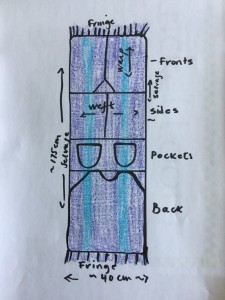

Here’s my singles laid out for plying: (from left to right) a single, chain-ply three-ply, two-ply, and three-ply.

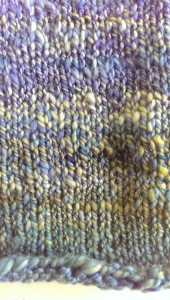

Here they are plied:

The three-ply appears obviously different. But the proof is in the pudding (or as Rachel says, the proof of the pudding is in the tasting), so I did some swatching:

I didn’t really enjoy spinning this roving because it was a bit felted and didn’t draft very well. This resulted in a slubby single, but knit up I like the texture the slubs add. The colors and striping are the same as the roving. So if I like how it looks as a single, any plying is going to modify the colors and texture.

This swatch ended up being the most dynamic, color-wise. The areas of high contrast (the yellow bits) give it a marled look. Depending on the project, this could add a great deal of interest, or just make it busy. There is some color striping but it’s pretty random. The areas of low contrast, with blues plied with each other, are less vibrant than the same color in the single.

The chain-plied three-ply I expected to maintain the striping of the single swatch, just with thicker yarn, but the plying softened the color changes, and actually muted the colors:

I picked the three most contrasting singles for the three-ply to try and get the maximum color variation:

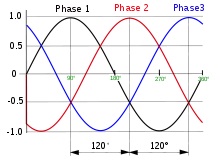

The color changes have been blended out, so while there are areas of different color, the overall effect is a very gradual shift. Except for one spot where all the slubs lined up, the slubbiness is gone too. I have an automotive background, so this really reminds me of a three-phase alternator, so made to cut down on the low-spots in alternating current and provide a smooth, constant flow:

So: when plying with the same colorway, the ply is going to change the color. A two-ply will only have half of each each single, a three-ply will only show a third of each single. I definitely should have swatched the single I’d spun from my candy-dyed roving to see if I liked it as-is. Swatch early, swatch often!