Sal tells me I need to take more notes while I work. It’s because when she asks me for measurements and quantities I used for a project I usually don’t have a good answer.

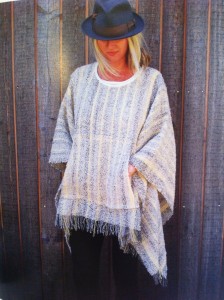

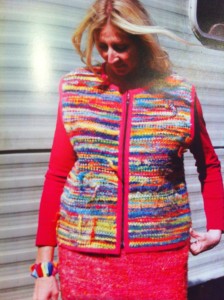

Recently I finished weaving a length of fabric to make a dressy jacket and although I didn’t make any notes I’m going to put down some thoughts, tips and tricks here. This way Sal will have no excuse not to get started on her Chanel-style jacket. She’s going to weave and sew it for her next guild challenge which is all about tweed. It needs to be done by February. No pressure Sal!!

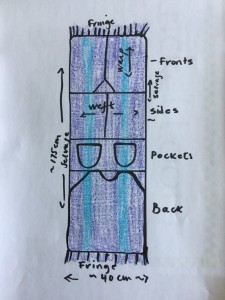

Pick a commercial sewing pattern: If you are new to sewing or simply new to sewing with handwoven, don’t pick a pattern that’s overly complicated. Keep it simple. I picked NewLook 6351. The jacket is comprised of two sleeves, four front pieces, two back pieces and a facing piece. If you are using a thick piece of cloth, you need to think about how your seams are going to work and whether you will need a lining. That could be tricky to do with a thick piece of cloth.

Make a muslin: A muslin is a trial run of your garment that can be adjusted for fit. I use muslin cloth–a creamy coloured cotton–when I’m making dresses or trousers, because when you spend a lot of time making your own garments, you want it to fit. Check out the Tilly & the Buttons site for everything you need to know about muslin (toile) making.

I’ve never had a garment that I haven’t had to adjust. There is some great information about adjusting patterns on the Colette blog and Sewalongs. You don’t want to spend time weaving cloth and then sewing it only to have something that doesn’t fit. If you need help making alterations on the muslin, I would ask an experienced sewist for help.

Once you have your muslin completed and fitted, hold onto it. This is now your pattern.

You might want to try a sample garment in fabric in a similar in weight to your handwoven. Make your mistakes on the sample, not on your handwoven.

Do the math: The New Look jacket pattern calls for about 1.3 meters of 150cm wide fabric. I have a 80 cm (32 inch) loom and therefore I decided to weave 3 meters of cloth. I put a 4 meter warp (I wanted about 60cm extra warp for wastage) on the loom using a 50/10cm dent reed (12.5 dents per inch). I used almost the entire width –400 dents. Four meters multiplied by 400 dents equals 1600 meters of warp yarn.

I was far less precise with the warp meterage. My idea was to use stash yarn and luckily I had plenty.

I’d estimate I used 700 meters of yarn in the warp (3 picks per cm x 300cm x 80 cm/100). I used different yarn weights and even some roving in there, plus a bunch of my handspun bouclé, so that’s very much a ballpark figure.

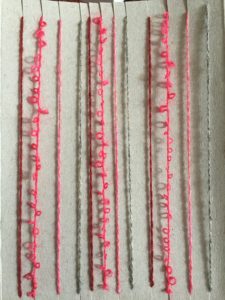

Sample and warp: Before I dressed the loom, I made some cardboard squares to test out colour combinations. This was a quick and easy way to see how the colours and yarns I picked out looked together. I wanted to see the warp colour sequence and get a feel for how the yarns worked together.

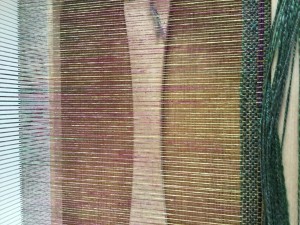

The next step was to dress the loom (i.e. warp it) which I did using the direct warping method.

Once thing I wish I hadn’t done was use boucle in the warp. BAD IDEA. It stuck and snapped and was a total nightmare. Avoid!

Weave: Weave, weave and weave. I didn’t follow a pattern and just went with by colour and texture. I used this project to do some stash busting. Very gratifying.

Finish your cloth: Once you’ve woven your little heart out, remove the cloth from the loom. Give it a gentle wash in some hand hot water and a small amount of gentle soap. Rinse then carefully squeeze out the water. Do not wring your fabric. Remove excess water by rolling your cloth in a towel. Hang out on the line to dry.

Part two: Cutting your cloth. Coming soon. Once I do it.